Introduction

In today’s evolving energy landscape, the demand for high-efficiency electrical materials is accelerating. One of the most important materials at the core of power transmission and distribution systems is cold rolled grain oriented steel. This specialty steel, commonly abbreviated as CRGO, is a key component in manufacturing high-performance transformer cores.

Used extensively across Europe and the Middle East, cold rolled grain oriented steel contributes significantly to reducing core losses, improving magnetic efficiency, and supporting the reliability of national and industrial energy systems.

Understanding Cold Rolled Grain Oriented Steel

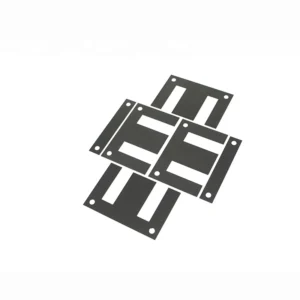

Cold rolled grain oriented steel is a type of silicon steel engineered to exhibit excellent magnetic properties in a single direction—typically aligned with the rolling process. This characteristic is crucial for minimizing energy loss in electrical transformers, where the magnetic flux predominantly flows in a fixed path.

The “grain orientation” achieved through a controlled annealing process results in a material that provides very low core loss and high permeability, making it superior to non-oriented electrical steels in transformer applications.

Key characteristics include:

- Low hysteresis loss

- High magnetic permeability

- Excellent dimensional and surface stability

- Superior insulation resistance due to specialized coatings

These attributes make cold rolled grain oriented steel indispensable in the design of efficient and durable power transformers.

Manufacturing Process

Producing cold rolled grain oriented steel involves multiple complex steps, each contributing to the material’s unique performance characteristics:

- Hot Rolling: Steel slabs are initially hot-rolled into thinner sheets.

- Cold Rolling: The hot-rolled sheets undergo precision cold rolling to reduce thickness and improve surface finish.

- Decarburization Annealing: Carbon content is minimized through high-temperature treatment to prevent magnetic aging and increase consistency.

- Secondary Recrystallization: This step is key to achieving the Goss texture, where grains align in the <110> direction to support optimal magnetic flow.

- Coating: An insulating surface layer is applied to improve electrical resistance and prevent eddy currents.

- Magnetic Domain Refinement (optional): Laser scribing or mechanical techniques may be used to further reduce core losses by refining the domain structure.

Applications in the Power Industry

Cold rolled grain oriented steel is used in critical applications where efficient magnetic flux is essential. These include:

1. Power Transformers

Power transformers are vital for stepping up or stepping down voltage in grid systems. CRGO steel ensures minimal no-load losses, enabling high efficiency over long operational lifespans. This makes them suitable for:

- Substation transformers

- Interconnected grid systems

- Transmission substations

2. Distribution Transformers

Smaller-scale transformers used in residential and commercial distribution networks rely on CRGO steel for optimal voltage regulation with low energy dissipation. These are widely used by utilities in both rural and urban environments.

3. Instrument Transformers

In metering and protection systems, CRGO steel ensures magnetic precision and thermal stability, which is critical for accurate energy measurement and fault detection.

4. Renewable Energy Transformers

As solar and wind power expand in the Middle East and Europe, CRGO steel is being deployed in specialized transformers for inverters and power electronics, ensuring stable energy flow and system efficiency.

Market Trends in Europe and the Middle East

Europe

The European market is moving rapidly toward energy-efficient infrastructure, largely driven by the EU’s strict environmental regulations and green energy targets. Upgrading old transformer systems with newer CRGO-based models is a growing trend.

European manufacturers now demand high-grade cold rolled grain oriented steel to meet Ecodesign requirements that reduce standby losses and support grid stability.

Middle East

Rapid urbanization, electrification, and the development of renewable energy sectors in the Gulf Cooperation Council (GCC) countries are creating high demand for advanced electrical steels. From smart cities to mega infrastructure projects, cold rolled grain oriented steel is being used to build a more reliable and robust power backbone.

Saudi Arabia, the UAE, and Qatar are especially active in adopting new transformer technologies to meet growing electricity consumption and to minimize power losses across the grid.

Technical Advantages

Cold rolled grain oriented steel offers several benefits over other materials:

- Higher Magnetic Flux Density: Enables smaller and lighter transformer designs.

- Reduced Core Losses: Essential for energy savings in 24/7 operating systems.

- Thermal Resistance: Performs well under high ambient temperatures—ideal for Middle Eastern environments.

- Consistent Performance: Grain alignment ensures predictable magnetic behavior, critical for sensitive applications.

- Regulatory Compliance: Meets or exceeds standards such as IEC 60404 and EN 10106.

Challenges and Considerations

While CRGO steel offers many advantages, its production and use also pose certain challenges:

- Manufacturing Complexity: Requires highly controlled production environments, limiting supplier availability.

- Cost Factor: Higher cost compared to non-oriented steel, although long-term energy savings often offset initial investment.

- Supply Chain Pressure: Global demand has increased, and geopolitical factors may impact material availability.

Manufacturers and utilities are now turning to regional suppliers and investing in long-term procurement strategies to ensure a steady supply of high-quality cold rolled grain oriented steel.

Sustainability and the Future

The energy-saving potential of CRGO steel contributes significantly to global sustainability goals. Replacing older transformers with CRGO-based ones can reduce energy losses by 30–40%, leading to:

- Lower CO₂ emissions

- Reduced electricity generation needs

- Enhanced grid performance

Ongoing research focuses on:

- Laser scribing advancements

- Thinner gauge CRGO for compact designs

- Eco-friendly coating materials

- AI-driven quality control systems

These innovations ensure that cold rolled grain oriented steel remains central to the future of smart, sustainable, and efficient power systems.

Conclusion

Cold rolled grain oriented steel is a cornerstone of modern power transmission and transformer engineering. With its excellent magnetic properties and energy-saving benefits, it addresses the global challenge of efficient electricity use. As the need for energy grows in Europe and the Middle East, the role of CRGO steel in delivering sustainable power solutions will only become more prominent.

Manufacturers, electrical utilities, and infrastructure developers should view cold rolled grain oriented steel not just as a raw material, but as a strategic asset in building a cleaner, more efficient future.