Company Name] Expands International Operations with Cold Rolled Electrical Steel Exports

As global demand for high-efficiency energy solutions continues to rise, [Company Name] is proud to announce a significant expansion in its export operations for cold rolled electrical steel. With new shipments headed to Europe and the Middle East, this marks a major milestone in the company’s commitment to supplying premium-grade steel to power essential industries across the globe.

Used extensively in electric motors, power transformers, generators, and smart grid infrastructure, cold rolled electrical steel is an indispensable material in modern energy systems. The company’s recent efforts to strengthen its international distribution channels demonstrate not only growing market demand, but also confidence in the quality and consistency of its products.

Meeting the Growing Global Demand

The global shift toward renewable energy, electric mobility, and smarter industrial automation has created a surge in demand for materials that offer high magnetic performance and low energy loss. Cold rolled electrical steel has emerged as a key enabler of this shift, offering superior magnetic permeability, minimized core losses, and exceptional dimensional precision.

[Company Name] has responded to this market trend by investing in state-of-the-art production equipment, expanding capacity, and streamlining its international logistics operations. These efforts have made it possible for the company to serve customers in more than 30 countries, with a growing footprint in both mature markets like Germany and emerging industrial hubs such as the UAE and Saudi Arabia.

Strategic Shipments to Europe and the Middle East

In the past quarter alone, [Company Name] has successfully fulfilled several large-scale orders of cold rolled electrical steel for applications ranging from renewable power plants in Northern Europe to electric rail projects in the Middle East. These shipments include grain-oriented and non-grain-oriented grades tailored for the specific requirements of each client.

Europe: Electrification and Sustainability

In Germany, France, and the Netherlands, customers have deployed [Company Name]’s cold rolled electrical steel in:

- High-voltage transformer cores

- Industrial drive motors

- Renewable energy inverters

- Electric vehicle motor assemblies

European regulations continue to raise the bar for energy efficiency, making the demand for high-performance materials more critical than ever. [Company Name]’s CRGO (Cold Rolled Grain Oriented) and CRNGO (Cold Rolled Non-Grain Oriented) steel grades are engineered to meet EU standards such as the Ecodesign Directive and REACH compliance.

Middle East: Smart Infrastructure and Industry Growth

In the Middle East, a region undergoing rapid urbanization and electrification, [Company Name] has seen increased demand from:

- Utility providers upgrading national grids

- Industrial zones introducing automation systems

- Renewable energy developers building solar and wind installations

- Transportation infrastructure powered by electric drives

Shipments to clients in the UAE, Saudi Arabia, and Egypt have been configured to withstand high temperatures and variable voltage conditions—requirements that are common in the region’s diverse industrial landscape.

Production Excellence: A Competitive Advantage

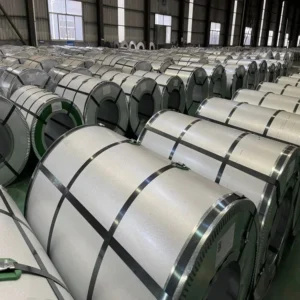

At the heart of [Company Name]’s international success is a vertically integrated production facility that specializes in advanced electrical steels. With high-precision cold rolling mills, vacuum annealing furnaces, and automated coating lines, the company produces cold rolled electrical steel that exceeds industry performance benchmarks.

Some of the notable technical features of its products include:

- Ultra-low core losses (W/kg)

- Thin gauge capabilities (down to 0.23 mm)

- Uniform grain alignment for CRGO

- Advanced inorganic insulation coatings for improved inter-laminar resistance

- High thermal and mechanical stability

Each batch undergoes rigorous quality control testing, including Epstein frame analysis, surface flatness inspection, and coating adherence evaluation to ensure consistent results for clients.

Sustainable and Responsible Manufacturing

As the steel industry shifts toward more sustainable practices, [Company Name] is committed to leading by example. The cold rolling and annealing processes have been optimized to reduce energy consumption and emissions. Furthermore, the company adheres to ISO 14001 environmental management systems and uses REACH-compliant coating materials.

In recent years, [Company Name] has:

- Reduced water usage by 28% through closed-loop cooling systems

- Increased energy efficiency in annealing furnaces by 15%

- Achieved 90% recyclability of production scrap

- Transitioned to low-VOC coating solutions

These achievements support not only corporate ESG goals but also align with the sustainability priorities of international clients.

Customer-Driven Innovation

A major differentiator for [Company Name] is its customer-first approach. In addition to standard product offerings, the company provides:

- Customized grades based on magnetic and mechanical specifications

- Coil slitting and packaging tailored to customer machine setups

- On-site technical support for transformer and motor manufacturers

- Flexible shipment scheduling and full logistics support

The goal is to ensure that every partner—whether in Rotterdam or Riyadh—receives the product exactly as needed and on time.

Testimonials from International Clients

“We’ve tested electrical steel from multiple sources, but [Company Name] has provided the most consistent quality and excellent post-sale support.”

– Procurement Manager, Transformer Manufacturer, Germany

“Their CRNGO coils worked perfectly in our motor production line. The technical team also helped us optimize lamination stacking.”

– Lead Engineer, Motor Manufacturer, UAE

Such endorsements underline the brand’s growing reputation across global energy and industrial sectors.

Looking Forward: Expansion and R&D

In response to surging demand, [Company Name] is in the final stages of completing an additional 60,000 metric tons of annual capacity for cold rolled electrical steel. The new production line is equipped with Industry 4.0 features, enabling tighter control of dimensional tolerances and faster turnaround times.

The company is also investing in next-generation R&D, focusing on:

- Hybrid magnetic laminates for e-mobility applications

- Nanocrystalline coatings for high-frequency efficiency

- Ultra-thin, high-strength CRNGO for compact motors

- Smart materials for AI-controlled electric machines

These innovations will further solidify [Company Name]’s position as a global leader in electrical steel technology.

Conclusion

As energy efficiency becomes central to global infrastructure, materials like cold rolled electrical steel will define the success of smart technologies and clean energy systems. [Company Name] is proud to contribute to this transformation by delivering world-class electrical steel products to partners across Europe and the Middle East.

With an unwavering focus on quality, sustainability, and customer collaboration, the company is poised to meet the future with resilience and innovation. Whether in transformers powering cities or motors driving new industries, [Company Name]’s cold rolled electrical steel will continue to be a core ingredient in building a smarter, greener world.